This Mondo Nuvinci review was written by Val Kleitz, originally posted to phred.org, and is blogged here with permission. Below are related links and videos.

This Mondo Nuvinci review was written by Val Kleitz, originally posted to phred.org, and is blogged here with permission. Below are related links and videos.

Since before the turn of the twentieth century, the development of gearing systems for bicycles has inspired a vast amount of technical invention and innovation. The overwhelming variety of drive train styles has been the subject of many articles and several books, and new developments continue to appear. One goal that has obsessed inventors almost from the beginning has been the creation of a continuously variable drive system. There have been many attempts to build such a system, which would allow the rider to change the gear ratio throughout the range without being limited to specific gear increments. Until now, all the imaginative approaches to this mechanical conundrum have been either completely unworkable, or inappropriate for use on bicycles.

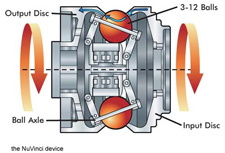

The NuVinci Continuously Variable Transmission hub has finally achieved this goal: a bicycle drive train of moderate weight, good efficiency and durability under torque, with an infinitely adjustable gear ratio and a range of 350%. As one of the first US distributors of this revolutionary hub, Seattle Bike Supply recently received a sample, which we promptly built into a wheel, installed on a bike, and began testing under the toughest conditions we could impose. I had the privilege of riding it for the first week, and these are my impressions.

The hub itself is larger and heavier than any other internally geared hub, but not unreasonably so. The 150mm flange means that wheels must built in a two cross pattern, and the resulting wheel will shift the center of gravity rearward on the bike. Initial installation requires careful attention to the instructions, as the shifting mechanism must be properly installed on the axle, but once the set up process is complete, removing and reinstalling the wheel is only slightly more complex than it would be for a standard bolt on wheel, and easier than a coaster brake wheel (our wheel was set up for disc brake use — there is also the option of using the Shimano roller brake, which would make removal and reinstallation more difficult). The shifter uses a double cable system, and is easy to install when assembled with cables and axle mounted shift box. Setting up the cables and shift box is a somewhat complex process, but not too technically sophisticated. The twist grip style shifter makes one full revolution going from the low end of the range to the high end, and has an unusual display which indicates the ratio without numbers. In the lowest ratio, a red line forms an inchworm-like hump, indicating the sort of hill you can climb in that ratio, and as you shift up, the line flattens out, until it is perfectly straight for the highest ratio.

Once we had a working bike, I began using it as my primary commuting bike. My daily commute is 8 miles one way, and the return trip involves 1 ¼ miles of 9.6% uphill grade. To make things more fun, it is winter in the Pacific Northwest, and rain, grit, mud and freezing temperatures add to the conditions that any bicycle must endure. I am also the sort of person who always needs to have a certain amount of paraphernalia (tool kit, thermos, lunch, rain gear, first aid kit, etc.) and cargo space for running errands. I never travel light, so I was towing a two wheel cargo trailer at all times during this week of testing, with a minimum of 20 lbs. on the trailer.

During the first day of riding, I did have some minor problems with the axle slipping in the dropouts, but this was easily rectified with more torque on the axle nuts. Once the wheel was properly secured, I was unable to cause any sort of malfunction whatsoever, and I did try.

The function of this hub is different than anything you have ever ridden. There are no “gears” as we know them. The range built into the hub is the equivalent of having an 11-38 tooth cassette, but the rider does not select a gear within this range. Instead, you simply adjust the ratio to match your riding preference and the terrain. It feels like turning a dimmer switch or the volume dial on your stereo. The hub is always “in gear” because the mechanism is always engaged, and always capable of transmitting the pedaling torque to the rim. Because of this, there is no way to miss a shift, and no need to worry about when you should shift. You can always shift, whether pedaling, coasting or stopped.

One of the best aspects of this is that it makes shifting simple. It is no longer something you need to think about at all; if you want to shift, you shift, any time, even when stopped. Even so, using the hub to its best advantage does involve learning some different habits. During the first day of riding, I found myself waiting until my cadence was high enough to get into the next gear, a good habit with any other gearing system, but totally unnecessary with the NuVinci. When accelerating, it is possible to shift continuously, keeping your cadence constant as you go from a stop up to cruising speed. If you shift a little too far, and find yourself in a ratio that is a bit too high, adjust back down a little — there is no trauma, no hesitation, no chain slipping.

Once I got used to shifting whenever I felt like it, I found that the hub gave me some very useful feedback about my pedaling stroke. The manufacturer states that you can shift the hub under load, and while this is true, it is also true that any system under load will resist shifting. The more force you are putting on the chain, the more force it will require to move the shifter. If you have consciously developed the habit of relieving the pressure on the pedals when your hand shifts, this will be no problem, but if you do shift this hub under pressure, you will find that it tells you exactly where the “dead spot” is in your pedaling stroke. Under rapid acceleration, with moderate pressure on the shifter, the hub shifts in small increments every time your foot hits that spot. I found that in some circumstances, I actually had almost no dead spots in my stroke, and at other cadences, on different terrain, I seemed to have three. Very educational; after a while the feedback between feet and shifting hand becomes totally instinctive, with no intervention from the brain at all.

The ease of adjusting the ratio also led me to discover an interesting riding strategy — I found that when my legs were laboring on long upgrades, I was able to shift down just slightly and spin a bit faster, sometimes just for two or three pedal strokes, and then shift back up into the original ratio without any trouble. With a conventional gearing system, the need must be dire before this sort of multiple shift is worth the trouble.

I did try to put as much torque on the hub as I could, to see if I could break anything, with no success. After one grocery run, I chose the steeper of two possible routes home to haul the 60 lbs of trailer and supplies home, but even muscling over speed bumps on an extreme slope from a dead stop using 180mm cranks seemed to have no effect on the hub. I never felt any slippage in the hub, though by the end of the week the chainring I had used was showing signs of extreme stress.

The factory specs on torque state that the chainring should be at least twice as large as the cog on the hub, and this is how it was set up for this test, with a 19t freewheel and a 38t chainring. With this combination, the lowest ratio available gives the equivalent of a 1:1 gear, in which the rear wheel rotates once for each crank revolution. On this bike, a Redline Monocog Flight with Rhyno Lite rims, this translates to a 26” low gear. With the 350% range of the hub, this means that the highest ratio is a 91” gear — all in all, high enough and low enough to be useful in almost all situations. I did find myself using the full range, and I never felt that I really needed more, though I occasionally thought I might want it.

One of the main advantages of any internally geared system is resistance to extreme weather and dirty conditions, and the NuVinci is no exception to this. At the end of my week, I took the time to clean around a half a pound of road grit off the bike, and had to open the Euro style BMX bottom bracket to let the water out. Through all the slop that winter dumped on it, the hub remained impervious, and chain maintenance was the main concern, though there was never any question of derailing, as the chain line was essentially the same as any BMX drive train.

Overall, I would say that the hub performed excellently, and definitely lives up to its promise as a unique and revolutionary technology. The one feature that is lacking is some sort of protection for the shift box, which is mounted on the right side of the axle, and could be vulnerable in a crash, or when parking in a bike rack. It should be possible to modify a derailleur guard to prevent such damage, but it would be best if the manufacturer were to provide a guard. It is possible that future versions of the hub will be lighter, as well, but the current weight is not inappropriate for the comfort, city, commuting and cruiser style bikes that it is likely to be installed on. The great news is that we have continuous shifting at long last, and it is not only reliable, it’s fun!

Videos

Links

…We're riding townies, adventure, and mountain bikes. Find recommendations on our store page. As Amazon Associates we earn from qualifying purchases.